A New Era of Design and Manufacturing: Shaping the Future Through Innovation

Related Articles: A New Era of Design and Manufacturing: Shaping the Future Through Innovation

Introduction

With great pleasure, we will explore the intriguing topic related to A New Era of Design and Manufacturing: Shaping the Future Through Innovation. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

A New Era of Design and Manufacturing: Shaping the Future Through Innovation

The world of design and manufacturing is undergoing a rapid transformation, driven by an insatiable demand for more efficient, sustainable, and personalized solutions. This evolution is characterized by a relentless pursuit of innovation, pushing the boundaries of what is possible and reshaping industries across the globe. This article delves into the key drivers and trends shaping this dynamic landscape, exploring the profound impact of innovative design and manufacturing on our lives.

The Catalysts of Change:

Several key factors are propelling the evolution of design and manufacturing:

- Technological Advancements: The rise of powerful computing capabilities, advanced robotics, and sophisticated software tools has revolutionized the design and manufacturing process. Computer-aided design (CAD) and computer-aided manufacturing (CAM) systems allow engineers and designers to create complex models and simulations, optimize designs, and automate production processes with unprecedented accuracy and speed.

- Sustainable Development: Growing awareness of environmental challenges has driven a shift towards sustainable practices in design and manufacturing. This includes incorporating recycled materials, minimizing waste, reducing energy consumption, and adopting circular economy principles.

- Consumer Demand: Consumers increasingly demand personalized products, shorter lead times, and enhanced functionality. Manufacturers are responding by embracing mass customization, agile production methods, and incorporating user feedback into their design processes.

- Globalization and Digitalization: The interconnectedness of the global economy and the rise of digital technologies have fostered collaboration and knowledge sharing across borders. This has accelerated the adoption of innovative design and manufacturing practices, allowing companies to leverage global expertise and resources.

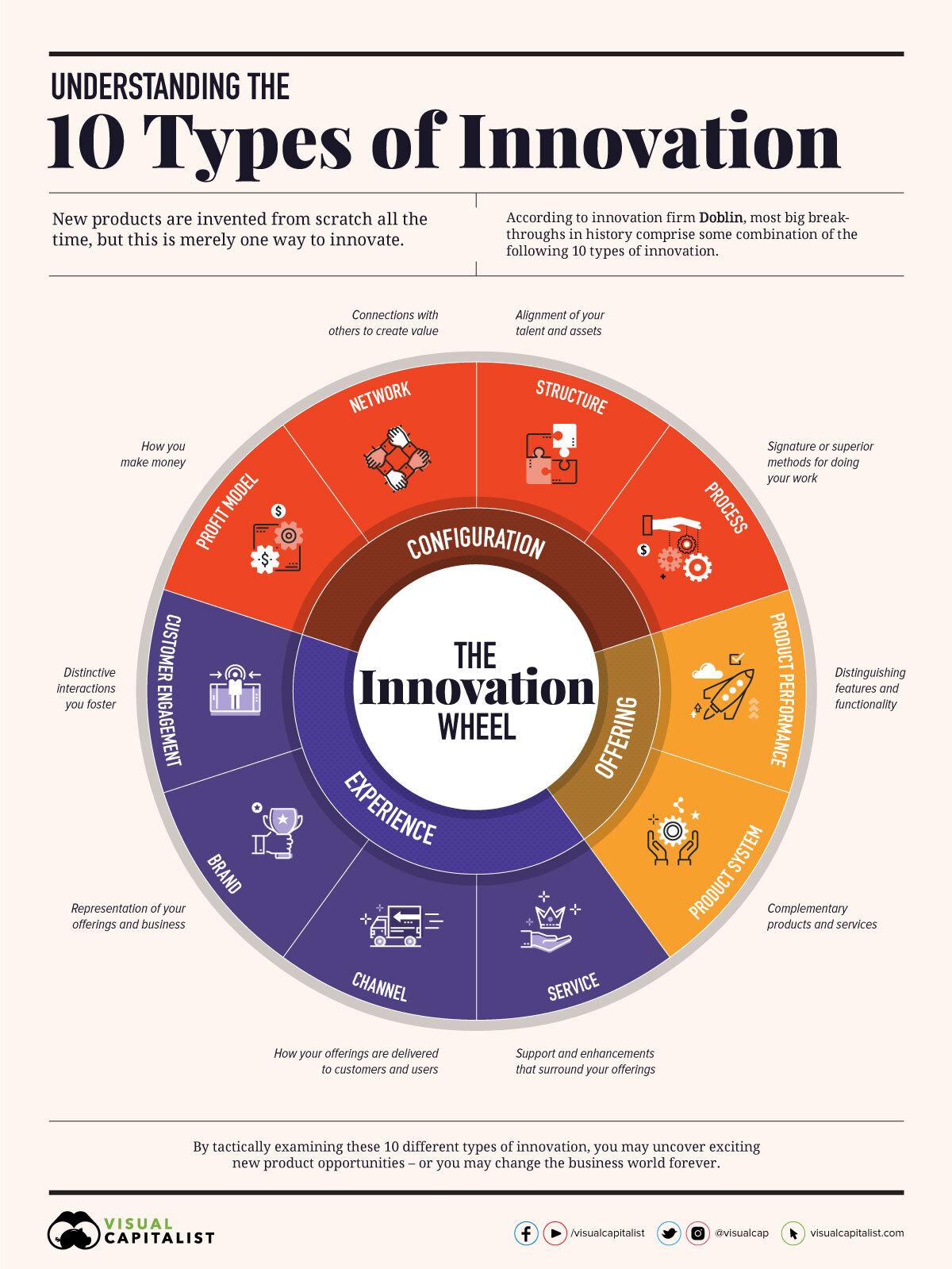

Emerging Trends and Technologies:

The convergence of these factors has paved the way for a wave of innovative design and manufacturing trends:

- Additive Manufacturing (3D Printing): This technology allows for the creation of objects layer by layer from a digital design, enabling the production of complex geometries and customized products. It is revolutionizing prototyping, reducing lead times, and enabling the production of highly customized and functional parts.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms are transforming the design process, enabling predictive modeling, optimization of designs, and the development of intelligent systems that can learn and adapt. These technologies are also being used to optimize production processes, predict equipment failures, and improve quality control.

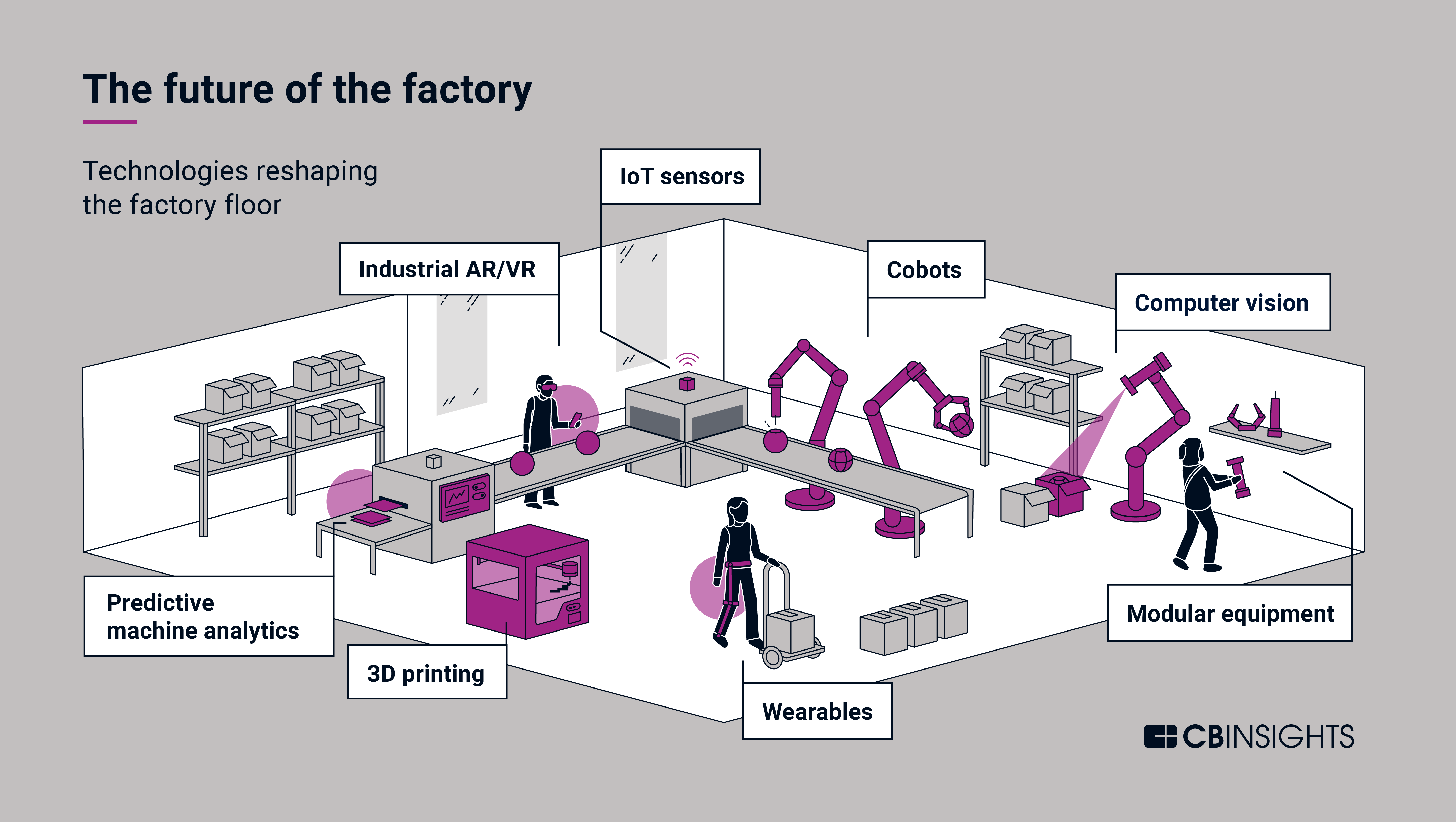

- Internet of Things (IoT): Connecting devices and systems through the internet allows for real-time data collection and analysis, enabling manufacturers to monitor and control production processes remotely, optimize efficiency, and ensure product quality.

- Cyber-Physical Systems (CPS): Integrating digital and physical systems allows for the creation of intelligent machines and systems that can interact with their environment and make decisions autonomously. This is leading to the development of self-optimizing manufacturing processes, automated quality control, and intelligent robots that can collaborate with human workers.

- Human-Centered Design: Placing the user at the center of the design process has become paramount. This approach focuses on understanding user needs and preferences, incorporating feedback throughout the design lifecycle, and creating products that are intuitive, accessible, and enjoyable to use.

- Biomimicry and Bio-Inspired Design: Drawing inspiration from nature to solve design challenges is gaining traction. Biomimicry leverages the efficient and sustainable solutions found in the natural world to create innovative products and processes. This approach is leading to the development of lightweight and durable materials, energy-efficient systems, and sustainable manufacturing techniques.

The Impact of Innovation:

The adoption of innovative design and manufacturing practices is having a profound impact across various industries and sectors:

- Increased Efficiency and Productivity: Automation, optimized processes, and data-driven decision-making are driving significant improvements in efficiency and productivity. This enables companies to produce goods faster, reduce costs, and enhance competitiveness.

- Enhanced Product Quality and Performance: Advanced design tools, simulation capabilities, and precise manufacturing processes allow for the creation of products with superior quality, durability, and functionality.

- Greater Customization and Personalization: Manufacturers are able to cater to individual customer needs and preferences by leveraging technologies like 3D printing and mass customization. This allows for the creation of unique and personalized products, enhancing customer satisfaction and loyalty.

- Sustainable Development and Reduced Environmental Impact: Innovative design and manufacturing practices contribute to a more sustainable future by reducing waste, optimizing resource usage, and minimizing environmental impact.

- Job Creation and Economic Growth: The adoption of new technologies and innovative practices is driving the creation of new jobs in fields like robotics, AI, and data analytics. It also fosters economic growth by enhancing competitiveness and enabling companies to create new products and services.

FAQs about Innovative Design and Manufacturing:

Q: What are the challenges associated with implementing innovative design and manufacturing practices?

A: Challenges include the initial investment in new technologies and infrastructure, the need for skilled personnel to operate and maintain these systems, the potential for disruption to existing processes, and the need for robust cybersecurity measures to protect sensitive data.

Q: How can companies overcome these challenges and successfully implement innovative design and manufacturing practices?

A: Companies can overcome these challenges by investing in training and development for their workforce, adopting a phased approach to implementation, collaborating with technology providers, and establishing clear goals and metrics to track progress.

Q: What are the ethical considerations associated with innovative design and manufacturing?

A: Ethical considerations include the potential for job displacement due to automation, the need for responsible use of AI and data privacy, and the impact of new technologies on the environment and society.

Q: What is the future of innovative design and manufacturing?

A: The future of innovative design and manufacturing will likely be characterized by further advancements in AI, robotics, and automation, the development of new materials and manufacturing processes, and a greater focus on sustainability and circular economy principles.

Tips for Embracing Innovative Design and Manufacturing:

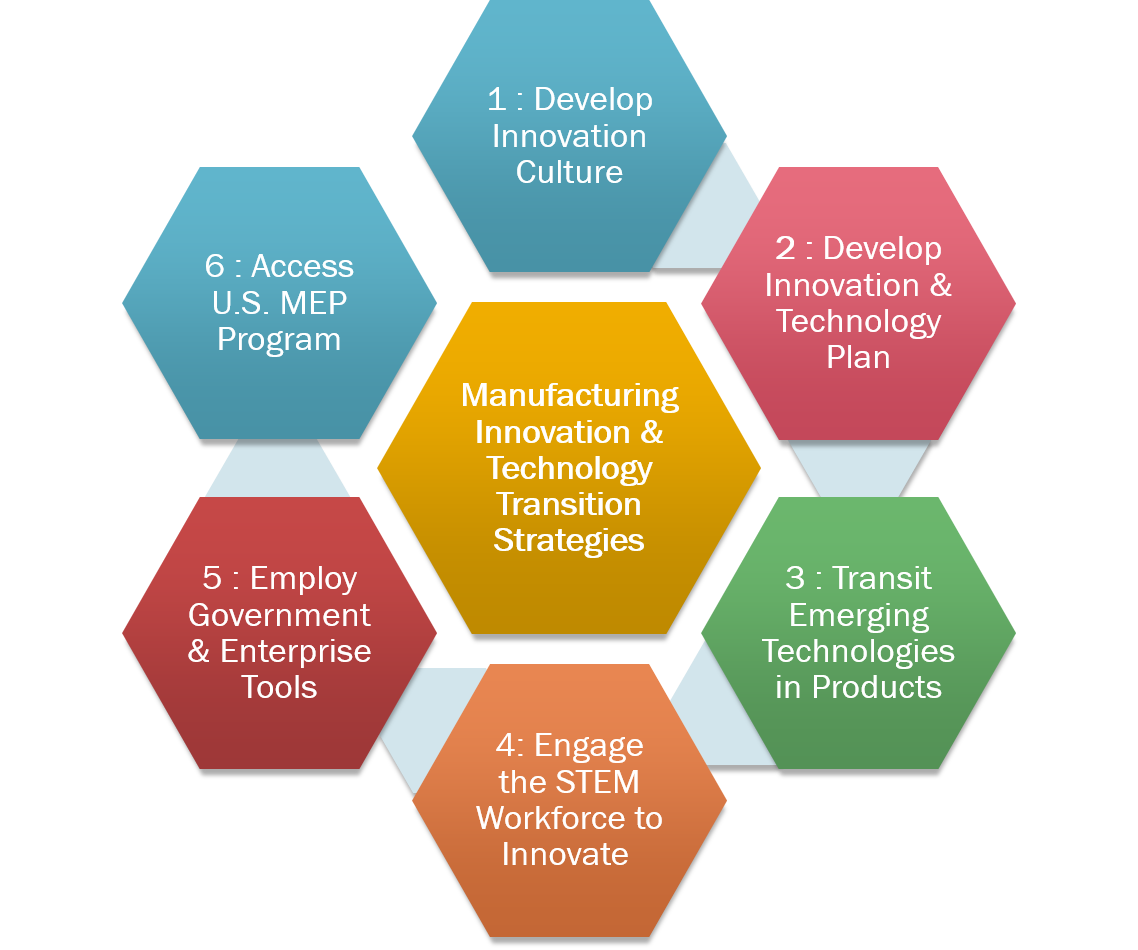

- Embrace a Culture of Innovation: Foster a culture that encourages experimentation, risk-taking, and continuous improvement.

- Invest in Training and Development: Equip your workforce with the skills and knowledge needed to operate and maintain new technologies.

- Collaborate with Technology Providers: Partner with technology providers to develop customized solutions and access cutting-edge innovations.

- Focus on Sustainability: Integrate sustainability principles into your design and manufacturing processes.

- Embrace Data-Driven Decision-Making: Leverage data analytics to optimize processes, improve efficiency, and enhance product quality.

Conclusion:

Innovative design and manufacturing are not merely trends but essential drivers of progress, shaping the future of industries and societies. By harnessing the power of technology, embracing sustainable practices, and focusing on human-centered design, companies can unlock new possibilities, create innovative solutions, and contribute to a more sustainable and prosperous future. The relentless pursuit of innovation will continue to drive the evolution of design and manufacturing, creating a world where products are more efficient, sustainable, and personalized than ever before.

Closure

Thus, we hope this article has provided valuable insights into A New Era of Design and Manufacturing: Shaping the Future Through Innovation. We thank you for taking the time to read this article. See you in our next article!